|

|

PDF UP550 Data sheet ( Hoja de datos )

| Número de pieza | UP550 | |

| Descripción | Program Controller | |

| Fabricantes | Yokogawa | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de UP550 (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

<<Contents>> <<Index>>

General

www.DataSShpeete4Uc.coimfications

GS 05E01C02-01E

Model UP550

Program Controller

s General

Model UP550 Program Controller can store up to 30

program patterns, and has a powerful control capability and

the user-friendly large numerical display. The UP550 features

as standard many functions which are necessary for various

control applications, and all of these functions such as

program setting function, control function, control computa-

tion function, signal computation function, etc. can be

configured by using the keys on the front panel. The

instrument has five types of control strategies, and also an

overshoot suppressing function "SUPER" and a heating

suppressing function "SUPER 2" built in as standard, as

well as an auto-tuning function.

s Main Features

• Extra-large digital display allows the indicated values to be

read even from a long distance. LEDs of 20 mm height are

used for the process variable display.

This is a five-digit display for heigher resolution.

• User-friendly, full-dot LCD display, capable of showing

not only control setpoints (SPs) and parameters but also

program patterns and deviation (DV) trend logs.

• Program setting function with storage capacity for up to 30

program patterns and 300 program segments, allowing the

controller to be used for a wide range of heat-treatment

applications.

• Five types of control function, including single-loop

control, cascade control, loop control with PV auto-

selector, enabling the operator to start control operation

immediately after simply entering the settings.

• The program pattern-2 retransmission function outputs a

program pattern by way of the retransmission output. This

function is used in combination with retransmission output

setup parameter RET 1 or RET 2, for which program

pattern-2 should selected, and is used for pattern

transmission to another instrument(available for UP made

1, 2, 6 or 7).

• Parameters and program patterns can be easily set using a

personal computer. ("Parameter setting tool (model

LL100)" sold separately is required.)

• Universal input and output enables users to set or change

freely the type of measured inputs, measurement input

range, type of control output, etc. from the front panel.

• Contact inputs (up to 7 points) and contact outputs (up to 7

points) can be employed and functions can be assigned to

each contact (the maximum number of points varies

depending on the specification code), with one additional

contact input available by specifying the appropriate suffix

code. (Contact outputs can be increased up to eight; see

"Number of Event/Alarm Outputs" on page 2 or "Contact

Outputs" on page 7.)

• Various communication function are provided. Communi-

cation is possible with personal computer, programable

logic controller, and other controllers.

UP550

UP550E

“E” indicates with the

model with expanded

functions.

s Functional Specifications

q Program Setting Function

The program setting function increases or decreases the value

of a target setpoint (SP) according to a given program pattern

that varies with time. The controller stores two or more

program patterns and the operator can switch between them

according to the operating status. Each program pattern

consists of multiple line segments (program segments). The

operator sets the time interval of each program segment using

the segment time or slope. The operator can also set such

instructions as the number of repeats, start/stop, and status

output (event output) for a given program pattern.

Number of program patterns: 30 maximum

Number of program segments per pattern: 99 maximum

Number of program segments: 300 maximum (sum of

segments for all program patterns)

Configurable number of events: 400 maximum (sum of

events for all program patterns)

Number of program repeats:

999 maximum, or unlimited repeats.

Segment time: 0 minute 0 s to 59 minute 59 s, or 0 h 0

minute to 99 h 59 minute.

Start/stop of program pattern:

Program patterns can be started (RUN),

stopped (RESET), paused (hold) or advanced

by means of contact inputs or from instrument

operation.

Switching between program patterns:

Achieved by contact inputs or from instrument

operation.

Target setpoint (SP)

Segment time

t1 t2

t3

t4

Segment Segment

No. 1 No. 2

Example of Program Pattern

t5

Segment

No. 5

GS 05E01C02-01E

© Copyright Feb. 2000 (YK)

2nd Edition Jul. 2004 (YK)

1 page

<<Contents>> <<Index>>

www.DataSheet4U.com

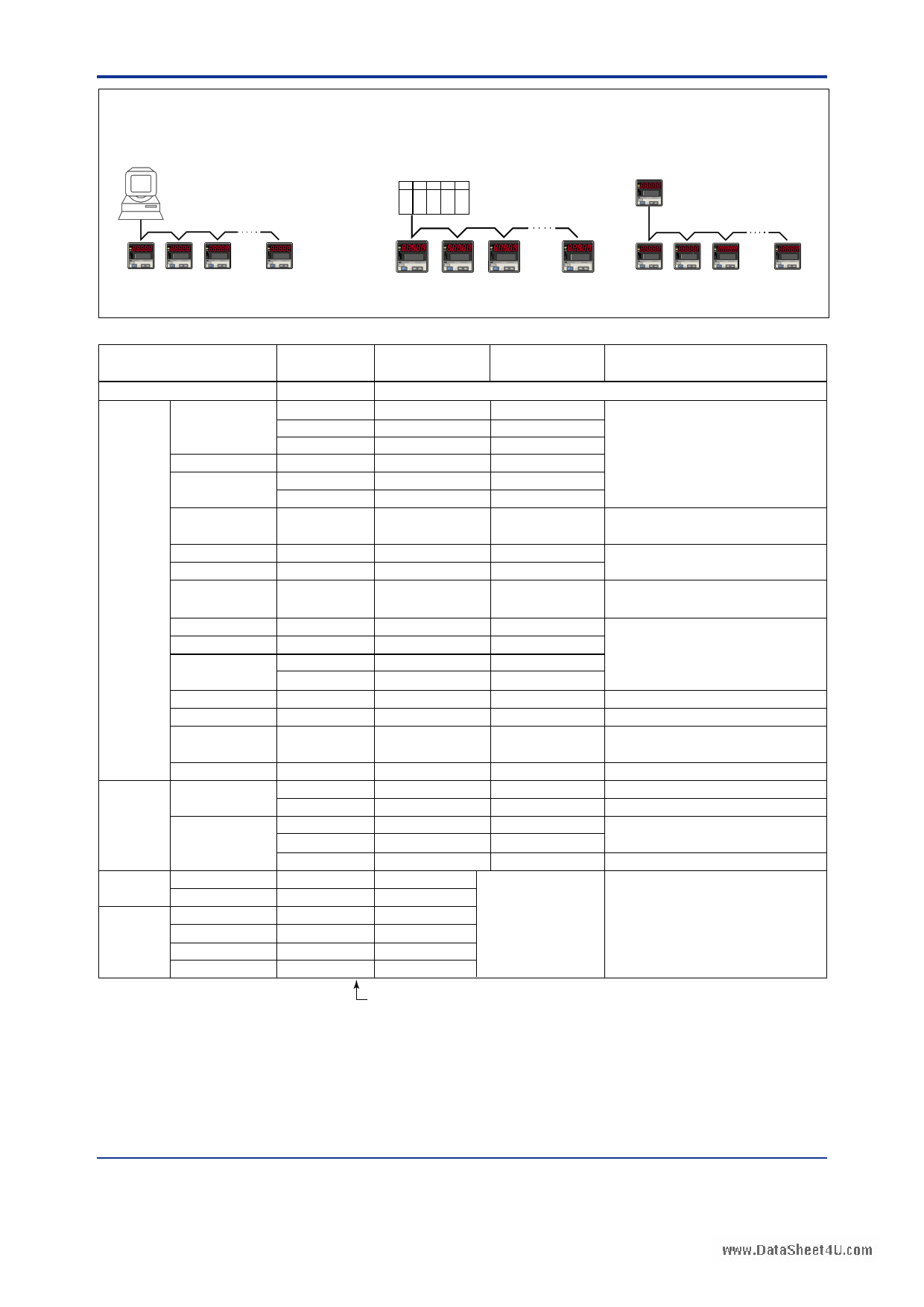

Examples of Communication System Configuration Diagram

(1) Personal computer link communication/

MODBUS communication

Personal computer

(2) Ladder communication

MELSEC-A

Programmable

controller

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

UP550

program controller

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

UP550

program controller

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

5

(3) Coordinated operation

UP550 (or UP750) program controller

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

PV

PV2

AL

1

2

3 REM

4 MAN1

MAN2

STP

CAS

A/M

SET/ENT DISP

UT750, UT550, UT520, UT350 or

UT320 digital indicating controller

Input type

Unspecified (When shipped from the factory)

Thermocouple K

RTD

J

T

B

S

R

N

E

L (DIN)

U (DIN)

W

Platinel 2

PR20-40

W97Re3-W75Re25

JPt100

Pt100

Standard

signal

DC voltage

0.4 to 2V

1 to 5V

0 to 2V

0 to 10V

-10 to 20mV

0 to100mV

Input range

code

Instrument

range (°C)

Instrument

range (°F)

Instrument accuracy*1

OFF Set the data item PV input type “IN 1” to the OFF option to leave the PV input type undefined.

typeK1

typeK2

typeK3

typeJ

typeT1

(1)

(2)

(3)

(4)

(5)

-270.0 to 1370.0°C

-270.0 to 1000.0°C

-200.0 to 500.0°C

-200.0 to 1200.0°C

-270.0 to 400.0°C

-450.0 to 2500.0°F

-450.0 to 2300.0°F

-200.0 to 1000.0°F

-300.0 to 2300.0°F

-450.0 to 750.0°F

±0.1% ±1 digit of instrument range at 0°C or more

±0.2% ±1 digit of instrument range at less than 0°C

• However, ±2% ±1 digit of instrument range for type K

at temperatures less than -200°C.

• However, ±1% ± 1 digit of instrument range for type T

at temperatures less than -200°C.

typeT2 (6)

0.0 to 400.0°C -200.0 to 750.0°F

typeB

(7)

0.0 to 1800.0°C

32 to 3300°F

±0.15% ±1 digit of instrument range at 400°C or more

±5% ±1 digit of instrument range at less than 400°C

typeS

(8)

0.0 to 1700.0°C

32 to 3100°F ±0.15% ± 1 digit of instrument range

typeR

(9)

0.0 to 1700.0°C

32 to 3100°F

typeN

(10) -200.0 to 1300.0°C -300.0 to 2400.0°F ±0.1% ± 1 digit of instrument range

±0.25% ±1 digit of instrument range for

temperature at less than 0°C

typeE

typeL

(11) -270.0 to 1000.0°C -450.0 to 1800.0°F ±0.1% ±1 digit of instrument range at 0°C or more

(12)

-200.0 to 900.0°C

-300.0 to 1600.0°F

±0.2% ±1 digit of instrument range at less than 0°C

• However, ±1.5% ±1 digit of instrument range for

typeU1 (13) -200.0 to 400.0°C -300.0 to 750.0°F

type E at temperature less than -200°C.

typeU2 (14)

0.0 to 400.0°C -200.0 to 1000.0°F

typeW

plati2

(15)

(16)

PR2040 (17)

W97Re3

JPt1

JPt2

Pt1

Pt2

(18)

(30)

(31)

(35)

(36)

0.0 to 2300.0°C

0.0 to 1390.0°C

0.0 to 1900.0°C

0.0 to 2000.0°C

-200.0 to 500.0°C

-150.00 to 150.00°C

-200.0 to 850.0°C

-200.0 to 500.0°C

32 to 4200°F

32.0 to 2500.0°F

32 to 3400°F

32 to 3600°F

-300.0 to 1000.0°F

-200.0 to 300.0°F

-300.0 to 1560.0°F

-300.0 to 1000.0°F

±0.2% ±1 digit of instrument range

±0.1% ± 1 digit of instrument range

±0.5% ±1 digit of instrument range at 800°C or more

Accuracy not guaranteed for temperature less than

800°C

±0.2% ± 1 digit of instrument range

±0.1% ± 1 digit of instrument range (Note1) (Note2)

±0.2% ± 1 digit of instrument range (Note1)

±0.1% ± 1 digit of instrument range (Note1) (Note2)

Pt3 (37) -150.00 to 150.00°C -200.0 to 300.0°F ±0.2% ± 1 digit of instrument range (Note1)

0.4 to 2V

1 to 5V

0 to 2V

0 to 10V

mV1

(40) 0.400 to 2.000 V Display range

(41) 1.000 to 5.000 V -19999 to 30000

(50)

0.000 to 2.000 V

Display span 30000 or

less (Decimal point

(51) 0.00 to 10.00 V position changeable)

(55) -10.00 to 20.00 mV

±0.1% ± 1 digit of instrument range

mV2

(56) 0.0 to 100.0 mV

Numbers in ( ) are the measurement input range codes that

apply when the communication function is used.

*1: Performance in the standard operating conditions (at 23± 2°C, 55± 10% RH, and 50/60 Hz power frequency)

Note 1:The accuracy is ±0.3°C of instrument range ±1 digit for a temperature range from 0 to 100°C

Note 2:The accuracy is ±0.5°C of instrument range ±1 digit for a temperature range from –100 to 200°C.

All Rights Reserved. Copyright © 2000, Yokogawa Electric Corporation

GS 05E01C02-01E 2nd Edition Jul. 30, 2004-00

5 Page

<<Contents>> <<Index>>

www.DatasShFeeut4cUt.icoonm Block Diagram for Loop Control with PV Switching

11

PV input 1

terminals

11 , 12 and 13

INPUT1

PV input 2

terminals

21 and 22

INPUT3

Contact input

DI7

DI1 DI2 DI3 DI4

DI8

DI5 DI6

Input selection

Input selection

Unit selection

Unit selection

Analog input range conversion Analog input range conversion

Analog input bias

Square root extraction

Analog input bias

Square root extraction

U3=2

Analog input filter

Analog input filter

10-seg. linearizer approx./bias 10-seg. linearizer approx./bias

PV input Switching (Temp. range, Temp. upper limit, or DI)

Burnout occurs when

the burnout of PV

PV input bias

PV input 1 (OFF)/

PV input 2 (ON)

input 1 or PV input 2

PV input filter

occurs.

Manual operation

Control computation

MAN

A/M

AUTO

Program

pattern selection

Program operation

Program

operation

Local

setpoint 1

Local

operation

Preset output

Output limiter

STOP RUN

OT1

Control

output

STOP/RUN switching

15 V loop Retransmission

power supply

output

RET2

RET1

OUTPUT1

OUTPUT1

OUTPUT1

OUTPUT3

Current or

Relay

pulse terminals terminals

16 and 17

1 , 2 and 3

Current*1

terminals

16 and 17

Current

terminals

14 and 15

PV event output

Time event output

Instrument alarm output

OUTPUT1

Relay*2

terminals

1 , 2 and 3

Time

event 5

DO1 DO2 DO3 DO4 DO5 DO6 DO7

PV PV Instrument Time Time Time Time

event 1 event 2 alarm 1 event 1 event 2 event 3 event 4

OUTPUT2

*1: Unavailable when control

output is current or pulse.

*2: Unavailable when control

output is relay.

*3: Only available for UP550-2ᮀ

Relay*3

terminals

48 , 49 and 50

Time

event 6

Legend

Terminal

Analog signal

Parameter

Contact signal

Function

All Rights Reserved. Copyright © 2000, Yokogawa Electric Corporation

GS 05E01C02-01E 2nd Edition Jul. 30, 2004-00

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet UP550.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| UP550 | Program Controller | Yokogawa |

| UP550 | Program Controller User Manual | Yokogawa |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |